Portable appliances are those that are not connected to any form of electrical outlet and can be carried around on their own power source. Portable appliance testing is a process that is used to identify whether the equipment has been damaged or not. Carrying out portable appliance testing can be a daunting task, especially if you are looking to do it yourself.

There are a few principles and procedures that must be followed while performing a PAT test. If you are looking for an easy way to make sure your equipment is performing as expected, then consider following the procedure, so you don’t miss out on anything. This article illustrates the principles behind PAT and the basics for new testers to practice portable appliance testing with ease.

Principles and basics of PAT testing for new testers

Portable appliance testing is a great way to find out if your equipment is safe to use, and what repairs need to be made. It’s also a great way to find out if your appliances are faulty or not working properly. Portable appliance testing is a bit more difficult than regular equipment testing, but it’s still very doable for beginners.

1. Get ready with all the tools for testing

To begin with, you are going to need a few items including a portable appliance tester, radiation meter, voltage meter, resistance thermometer, a digital multimeter and the parts of the equipment that needs to be tested. You might require other tools depending on the type of equipment being tested.

Furthermore, make a list of all the appliances you want to PAT test, so you will be prepared with the necessary tools required for testing. However, you can save time and leave this overwhelming task to professional and certified PAT testing companies and ensure the proper functioning of your electrical equipment.

2. Make sure the unit is certified to use

The next step in performing portable appliance testing is to determine whether the unit being tested has been certified for use in your area or not. If it has not, it should be taken out of service until it has been certified for use by your local authorities. Once you have determined that the unit has been properly certified, it’s time to get started.

3. Visual inspection

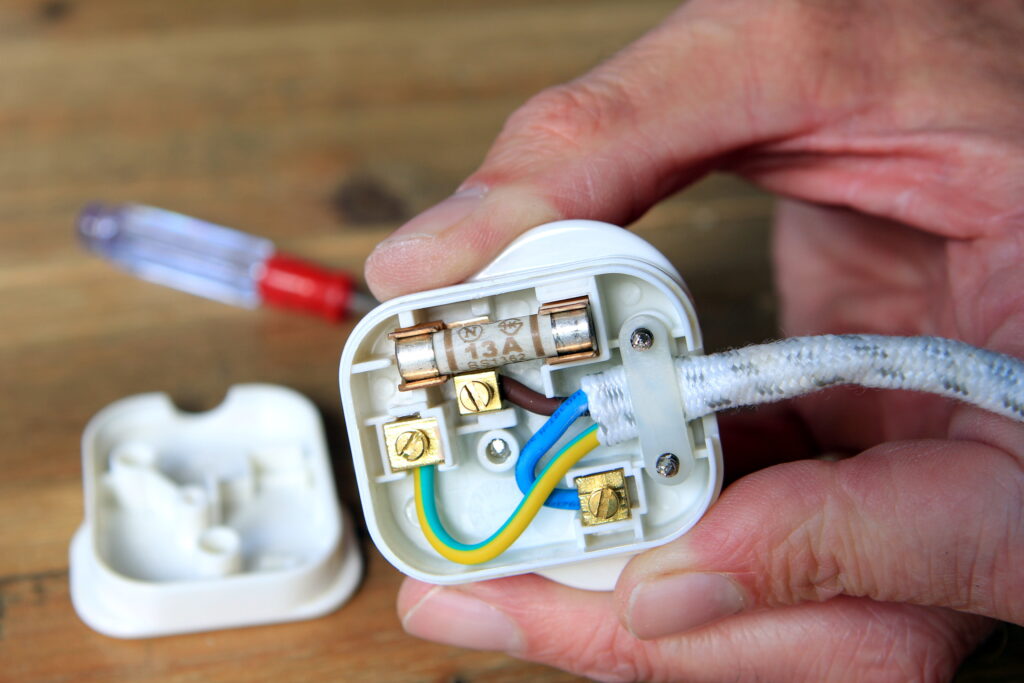

Visual inspection is one of the important parts of testing your electrical equipment. This involves looking at the appliance from all angles and determining if there are any signs of damage or malfunctioning parts such as burn marks on the cord and wires, frayed wires, or loose connections. If you find any damage or problems, take note of them so that you can deal with them later.

It is typically done by identifying any external damages or cracks on its body that may prove dangerous to use. If you see anything unusual about your appliance, you should take note of it so that you can report it to the manufacturer or repair shop later on down the line if necessary.

4. Check the circuit and fuse box

Now, continue checking the main circuit breaker or fuse box. Make sure that all fuses are turned on and that they are fully seated in their sockets before performing any tests on them. If possible, pull the plug on each circuit breaker before disconnecting it from its socket so that any current running through them can be safely removed before starting your tests. This will ensure that there are no electrical shocks present when performing any tests on them afterwards.

5. Make sure the temperature is normal

Checking the variation in temperature when the device is functioning is also a part of PAT testing. If the temperature rises too quickly then there must be some internal issue or malfunctioning. To perform this test turn on all of your appliances and keep an eye on them until they reach their normal operating temperatures.

Make sure that everything stays within its limits. Once your appliances have reached their normal operating temperatures, check them again and make sure this time without turning on any buttons or lights so that only light from the room can reach them.

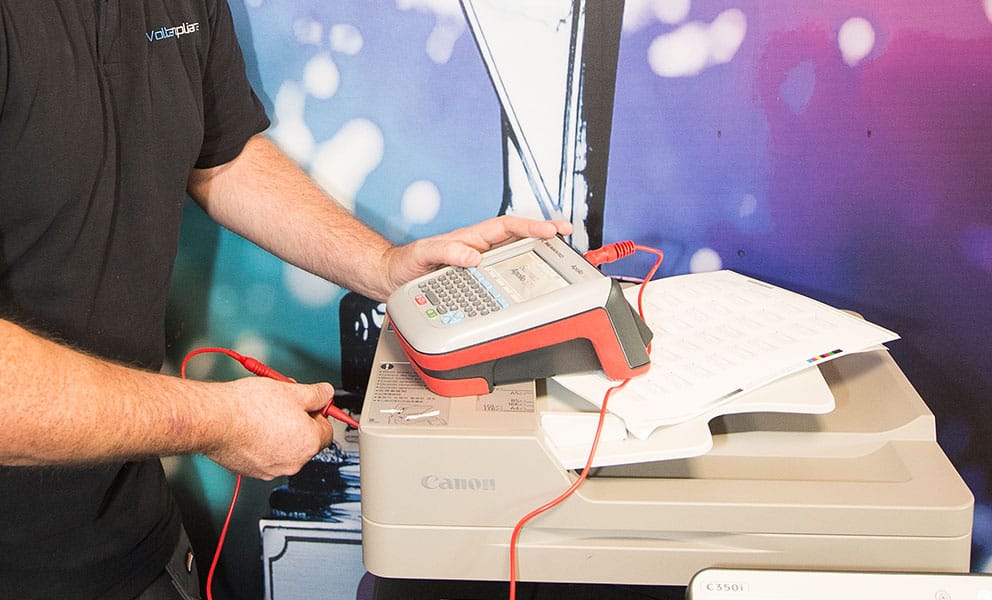

6. Electrical tests

There are a few other electrical tests that need to be done like earthing test, insulation test, leakage test, load test, flash test etc. These tests are a part of electrical testing that must be performed properly to ensure that there are no defects or malfunctioning.

This is extremely important as it allows you to identify any electrical problems with your appliance by testing it. You can do this by plugging it into an outlet and turning it on to see if it works or not. If it doesn’t work when plugged into the wall outlet, then there may be a problem with your appliance’s internal components.

Is it safe to perform portable appliance testing by yourself?

You can also perform these tests yourself by connecting an electric voltage tester to one of its terminals. If this test indicates that there is no power going into your appliance then you know that something may be wrong with it, be sure to contact someone immediately in order to prevent further damage.

However, if you feel too overwhelmed to follow all the procedures then you can always get PAT testing services. They have the right tools to carry out PAT tests and will make sure the appliances won’t cause any accidents or injuries in the future.

The Bottom-line

Portable appliance testing is an important part of the electrical field. There are different types of portable appliances that need to be tested to ensure they are working properly. It is used to test appliances such as air conditioners, refrigerators and other electronic devices.

Portable appliance testing involves taking a product apart and checking its parts for defects before you put them back together again. It’s a crucial step in assuring the safety of your customer’s lives and property as well as yours. Moreover, it’s something that everyone who works with appliances should know how to do.